Trump Time and Trump Savings are the keys to creating a new golden age.

Trump Time and Trump Savings are best illustrated by President Trump’s achievement with the Wollman Skating Rink in New York City.

The city bureaucracy began planning to overhaul the skating rink in 1974. It issued a plan in 1975 for $4 million. Then it spent $13 million from 1980 to 1986 and still did not have the skating rink fixed (it had stopped making ice in 1980 and was unusable for those six years).

Then-businessman Donald Trump’s apartment looked out over the skating rink. After six years, he could not stand the incompetence. He offered to fix the rink in less than six months for less than $3 million. Mayor Ed Koch and the New York City politicians hated the idea of turning it over to him. It would prove the city bureaucracy’s incompetence, but public pressure forced them to agree.

Trump finished the rink in four months—and 25 percent below budget.

When asked how he did it, Trump replied that it wasn’t rocket science. It was common sense and management. The full story is in President Trump’s “The Art of the Deal” and it is well worth reading.

The current bureaucracies and their giant corporate partners are in desperate need of the Wollman Skating Rink treatment.

Every government manager and government contractor should study the common sense, entrepreneurial lessons in the Wollman Skating Rink story.

The need for bold, dramatic change is enormous and worth trillions in savings over the next decade.

Consider that, according to a McKinsey study, U.S. construction productivity was lower in 2017 than it was in 1968.

Cost overruns and delays are a notorious and pervasive part of the current bureaucratic state-government contractor system. Large government bureaucracies collaborate with large corporate bureaucracies to create competition-free contracts – often on a cost-plus basis. This encourages waste and sloppiness. This is supported by congressional committees overwhelmed by armies of lobbyists. Some big government contractors can’t do engineering well, but they can do lobbying brilliantly.

The Ford Class Aircraft Carrier is years behind schedule and billions over budget. It has taken 10 years to build a single aircraft carrier. During World War II, the United States built more than 150 carriers in four years.

The Space Launch System is a classic case of big government, big business, big lobbyists and a passive Congress funding a mismanaged disaster. In 2012, NASA suggested SLS would cost $500 million per launch. The Government Accountability Office recently estimated SLS at $4 billion per launch.

So, it’s an eight-fold increase in cost — in percentage terms that is a 700 percent increase. This is after the government spent more than $30 billion in development costs on SLS, with only one test launch in 13 years of development.

The SLS Mobile Launcher II is 605 percent over budget. Estimated at $380 million it costs more than $2.7 billion – and this is just for the launch pad. Every president since 1989 has called for a return to the Moon and a path to Mars. Since then, we have spent more than $100 billion between Constellation and SLS. We have yet to send Americans around the Moon – let alone land on it.

Boeing has reported huge cost overruns combined with long delays in trying to build two new Air Force Ones leading to the Qatari Boeing 747 gift as an interim replacement.

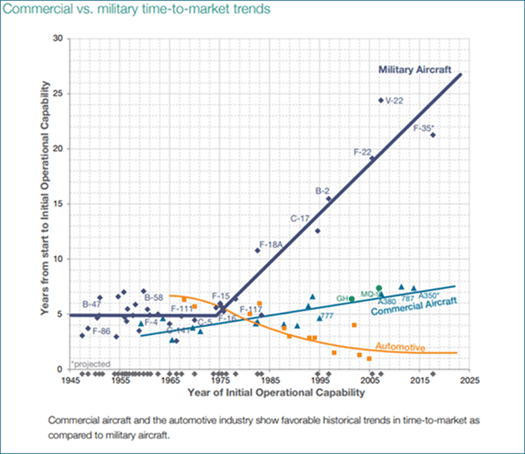

The problem of the Defense Department’s bureaucratic inability to move at the speed of the modern world is captured in a chart Senator Angus King developed:

The New York Subway extension is planned to be $4.3 billion per mile. It is already ten times more expensive than it would be in Paris or London (and this is before the cost overruns).

We have clear examples of less expensive and more rapid solutions. But the big bureaucracies, corporations, and armies of lobbyists convince Congress that the old order must be sustained regardless of cost or incompetence.

In his second term, President Trump has begun to institutionalize the concept of changing government from a process-oriented center of bureaucratic red tape and coercion into a collaborative partner with people and businesses. He is focusing government on achieving desired outcomes rather than simply spending years tied up in red tape.

The recent White House “Making Health Technology Great Again” conference illustrated a revolutionary development in using government as an initiator and convened to achieve great goals while keeping the vast bulk of the effort in the private sector.

Food and Drug Administration Commissioner Dr. Marty Markary and Center for Medicare and Medicaid Services Director Dr. Mehmet Oz recently wrote a piece in the Wall Street Journal titled “Cooperation Is the Key to MAHA.” The doctors outlined a brilliant strategy of reaching out to the private sector to collaborate with entrepreneurs and companies. They suggest we could achieve massive scales of change that are broader – and dramatically faster – than a bureaucratic approach. This collaborative approach would potentially unleash billions in resources, provide an entrepreneurial drive to get things done quickly, and foster real-time innovation.

Similarly, this model of public sector leadership with private sector resources could help America become a space-faring nation. It would dwarf traditional NASA-centric efforts and lead to radical breakthroughs in space – on a scale no peace time government program could match.

Just as then-citizen Trump reached out to a successful private sector ice rink manufacturer to solve the problem at the Wollman Skating Rink, this Trumpian recruitment of private sector entrepreneurs could rapidly help fix America’s biggest problems. The next great challenge for the Trump administration is to apply this aggressive, lean, results-focused model to the entire federal government.

The executive branch should establish programs to study “Trump Time and Trump Savings” as the operating principle for everything it does.

Whether it is building the Golden Dome, modernizing the air traffic control system, rebuilding railroads and mass transit, modernizing the Defense Department, or any other project, the “Trump Time and Trump Savings” model should be applied. This will require rewriting virtually all the regulatory controls that currently make the government slow and expensive.

For the most visible examples of dramatic savings in time and cost, simply look at SpaceX and Divergent 3D. Consider their potential impacts on cost and speed for projects such as the Golden Dome or the next generation air traffic control system.

The proven impact of SpaceX on cost and capabilities in space is a great start. SpaceX has revolutionized access to space to a degree that NASA, the U.S. Space Force, and Congress have yet to understand.

SpaceX has reduced the per kilogram cost of launching payloads to low earth orbit from more than $25,000 to less than $1,500. As of May 2025, SpaceX has launched approximately 8,723 Starlink satellites into orbit. The 33 engine Starship is currently having developmental challenges (just like the earliest SpaceX rockets). But, when complete, it will generate 2.3 times the thrust of the Saturn V rocket which took Americans to the Moon. It will again reduce the cost of launching payloads to about $10 per kilogram. This will further revolutionize access to space for people and materials. Estimates suggest Starship will be able to launch 100 people or 150 tons of cargo. One general at U.S. Space Command commented that it would be like launching a C-17 cargo plane into orbit or to the Moon.

Eric Berger’s book, “Liftoff” provides a vivid series of insights into how SpaceX became so proficient and inexpensive. Every project leader in government contracting or Congress should read it. Then reconsider the sales pitch of the lobbyists for the old order of delays, cost overruns, and cost-plus contracts.

The terrestrial parallel to SpaceX is Divergent 3D. It has the most effective and efficient factory in the world. Divergent 3D’s ability to manufacture at low cost and great speed leapfrogs past China—and all our global competitors.

General Atomics, which makes the Predator drone and a host of other defense systems, hired Divergent 3D to redesign a cruise missile. According to General Atomics’ own analysis, Divergent 3D produced a 98 percent reduction in parts, a 90 percent reduction in cycle time, a 40 percent reduction in variable costs, and a 50 percent reduction in development cost.

This process also reduced weight by 5 percent which allowed the defense product to fly faster and longer. Divergent 3D’s system dropped production time from 12 days to 1 day—and accelerated development from 18 months to four months.

It reduced the number of parts in one product from 184 to four. Divergent 3D uses an artificial intelligence component to continually redesign products in real-time. Its goal is to create more compact systems. The process then sends new designs to digitized production which uses 3D printing, robotics, and specialized chemistry to develop products.

Divergent 3D’s effectiveness is attested to by its most famous clients: Ferrari, Bugatti, and McLaren. In its own factory, it produced the Czinger 21C, the fastest street legal car in the world with a top speed of 219 miles per hour (its race configuration reaches 253 mph).

Recently, a Wall Street Journal reporter asked me if the Golden Dome missile defense system could really be built for $150 billion. He suggested that supposed experts thought it would take something like $1 trillion and at least a decade to build.

I told him if the traditional bureaucracies and the big bureaucratic contractors do it, it will clearly cost a lot more and take a lot longer. But, if you follow the cost and time reductions of SpaceX and Divergent 3D, it could be done remarkably quickly—and for less cost.

The Divergent 3D-SpaceX model may be the key to solving the Defense Department’s two great challenges.

The first challenge is figuring out how to leapfrog China and remain the most powerful modern military in the world. The second challenge is how to reduce costs in the wasteful bureaucratic system we have grown over the last 80 years.

The ongoing revolution in warfare, including artificial intelligence, robotics, and 3D printing is going to require constant innovation and constantly modified production at a low cost. This is impossible with the current bureaucratic-big contractor-lobbyist-congressional micromanagement system.

In this revolution in warfare, quantity on a scale we have never dreamed of is essential. Ukraine alone plans to build 4.5 million drones in 2025. Most of them are simple, but as Lord Nelson warned, “numbers annihilate.”

The process of getting to fast, low-cost development is not magic. Its most famous modern example was Skunk Works at Lockheed. It began in June 1943 when the Air Force desperately needed its first jet to respond to an emerging German threat. The first American jet was designed in one month. The Skunk Works was born and has been designing innovative systems for 82 years.

Its leader Kelly Johnson developed a set of principles which should be applied to every federal program and relentlessly insisted on by the President and Congress.

The Lockheed Skunk Works principles for rapid development:

1. The Skunk Works manager must be delegated practically complete control of his program in all aspects. He should report to a division president or higher.

2. Strong but small project offices must be provided both by the military and industry.

3. The number of people having any connection with the project must be restricted in an almost vicious manner. Use a small number of good people (10 percent to 25 percent compared to the so-called normal systems).

4. A very simple drawing and drawing release system with great flexibility for making changes must be provided.

5. There must be a minimum number of reports required, but important work must be recorded thoroughly.

6. There must be a monthly cost review covering not only what has been spent and committed but also projected costs to the conclusion of the program.

7. The contractor must be delegated and must assume more than normal responsibility to get good vendor bids for subcontract on the project. Commercial bid procedures are very often better than military ones.

8. The inspection system as currently used by the Skunk Works, which has been approved by both the Air Force and Navy, meets the intent of existing military requirements and should be used on new projects. Push more basic inspection responsibility back to subcontractors and vendors. Don’t duplicate so much inspection.

9. The contractor must be delegated the authority to test his final product in flight. He can and must test it in the initial stages. If he doesn’t, he rapidly loses his competency to design other vehicles.

10. The specifications applying to the hardware must be agreed to well in advance of contracting. The Skunk Works practice of having a specification section stating clearly which important military specification items will not knowingly be complied with and reasons therefore is highly recommended.

11. Funding a program must be timely so that the contractor doesn’t have to keep running to the bank to support government projects.

12. There must be mutual trust between the military project organization and the contractor, the very close cooperation and liaison on a day-to-day basis. This cuts down misunderstanding and correspondence to an absolute minimum.

13. Access by outsiders to the project and its personnel must be strictly controlled by appropriate security measures.

14. Because only a few people will be used in engineering and most other areas, ways must be provided to reward good performance by pay not based on the number of personnel supervised.

As then Representative Connie Mack, a former bank president, taught me in 1983 “you get what you inspect not what you expect.”

It will take a lot of changes in laws, regulations, and bureaucratic culture to get to Trump Time and Trump Savings but the long-term effects will be enormous.

All government managers and government contractors should adopt the principles of Trump Time and Trump Savings and the system of lean leadership. The resulting explosion in greater speed and lower cost will revolutionize America’s ability to outstrip all its potential competitors and create a true American Golden Age of opportunity, prosperity, freedom, and safety for all Americans.

For more commentary from Newt Gingrich, visit Gingrich360.com. Also, subscribe to the Newt’s World podcast.

Do you want access to more of Newt’s commentary? Become a member of Newt’s Inner Circle to get even more involved in our nation’s happenings. If you join today, you’ll receive a free autographed copy of one of Newt’s best sellers.

- Trump Time and Trump SavingsTrump Time and Trump Savings are the keys to creating a new golden age.

- Charity of the Month: Samaritan’s PurseIn recognition of its rapid and compassionate response to the devastating floods in Central Texas, the Gingrich Foundation proudly selects Samaritan’s Purse as its designated Charity of the Month for August.

- Trump’s Triumph: America’s Greatest ComebackIn this New York Times bestseller, author Newt Gingrich takes readers inside the most significant political comeback in American history and explains where the Trump movement goes from here.

- Newt’s World Episode 876: The Greatest American – Benjamin FranklinNewt talks with Mark Skousen about his new book, “The Greatest American: Benjamin Franklin, The World’s Most Versatile Genius.”

- Trump’s Trade TriumphThe news media’s analysts can’t seem to grasp the scale of President Donald J. Trump’s triumph in reshaping trade and the American economy.